High-Speed Check Weigher CWC H120/150

The High-Speed Check Weigher CWC H120/150 is an industrial machine designed for rapid and accurate weighing of products in high-volume manufacturing environments.

Designed for high-speed and high accuracy weighing especially for pharmaceutical industry.

Contact us for more

Our Experts are available to help

- Description

- BENEFITS OF USE

- SPECIFICATIONS

Description

Features

- EMFR loadcell, high-speed and accuracy weighing

- High-speed DSP technology

- Automatic product Guide, Zero Tracking and Trend Follow Up

- Metric/Imperial and Normal/EU regulation shift

- 13 inches touch screen with Android system which support multiple languages

- Large system memory which supports long term recording , fast seeking and recalling

- Points configurable real-time weight curve display

- Supports graphic based production statistic and analysis

- Equipped with BLDC motor which is performing high-speed and low dither

- Recording could be export to USB drive (CSV format)

- Data export by Ethernet port

- Various rejectors optional

- Tool- free conveyor removal

- SUS304 frame

The High-Speed Check Weigher CWC H120/150 offers several benefits in industrial settings:

- Increased Throughput: High-speed checkweighers are designed to process products rapidly, which significantly boosts throughput and production efficiency. This is particularly advantageous in high-volume manufacturing environments where speed is crucial to meet demand.

- Accuracy: These checkweighers are equipped with precision weighing mechanisms and advanced sensors, ensuring accurate measurement of product weights. This accuracy is vital for compliance with regulations, maintaining product quality, and minimizing giveaway or underfilled products.

- Versatility: The CWC H120/150 can handle a wide range of product sizes, shapes, and types, making it versatile for various industries such as food, pharmaceuticals, cosmetics, and more. This versatility ensures that the checkweigher can adapt to changing production needs without significant reconfiguration.

- Dynamic Adjustment: Many high-speed checkweighers are equipped with dynamic adjustment features that allow real-time adjustments to ensure optimal performance. This includes adjustments for conveyor speed, reject mechanisms, and weight thresholds, maximizing efficiency and minimizing downtime.

- Integration with Production Lines: These checkweighers are designed to seamlessly integrate into existing production lines, allowing for efficient workflow without causing disruptions. Integration capabilities include compatibility with conveyor systems, data management software, and other automation equipment.

- Quality Control: By accurately weighing products at high speeds, the checkweigher acts as a critical component of quality control processes. It helps identify underweight or overweight products, ensuring consistency in product packaging and adherence to quality standards.

- Reduced Product Giveaway: High-speed checkweighers help minimize product giveaway by ensuring that each product meets the specified weight requirements. This reduces waste and improves profitability by optimizing product yield.

- Compliance and Traceability: Many industries have strict regulations regarding product weights and packaging accuracy. The CWC H120/150 helps ensure compliance with these regulations and provides traceability through comprehensive data logging and reporting features.

In summary, the High-Speed Check Weigher CWC H120/150 offers increased throughput, accuracy, versatility, and integration capabilities, making it an essential component of modern manufacturing processes for quality control and efficiency.

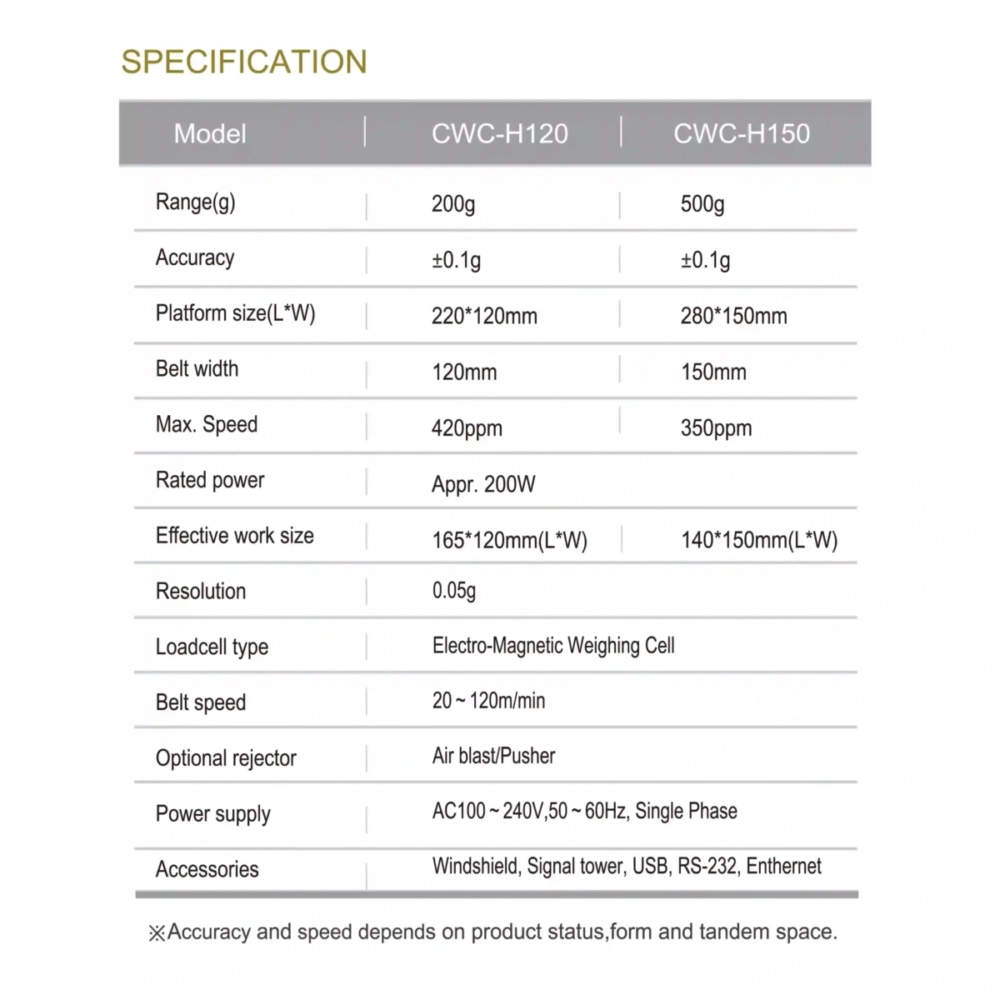

| Model | CWC – H120 |

| Range | 200g |

| Accuracy | ±0.1g |

| Platform size (L*W) | 220*120mm |

| Belt Width | 120mm |

| Max Speed | 420ppm |

| Rated Power | Appr. 200w |

| Effective Work Size | 165*120mm (L*W) |

| Resolution | 0.05g |

| Loadcell Type | Electro-Magnetic Weighing Cell |

| Belt Speed | 20~120m/min |

| Optional Rejector | Air blast/Pusher |

| Power Supply | AC100~240v, 50~60Hz, Single Phase |

| Accessories | Windshield, Signal Tower, USB, RS-232, Enthernet |

| Model | CWC – H150 |

| Range | 500g |

| Accuracy | ±0.1g |

| Platform size (L*W) | 280*150mm |

| Belt Width | 150mm |

| Max Speed | 350ppm |

| Rated Power | Appr. 200w |

| Effective Work Size | 140*150mm (L*W) |

| Resolution | 0.05g |

| Loadcell Type | Electro-Magnetic Weighing Cell |

| Belt Speed | 20~120m/min |

| Optional Rejector | Air blast/Pusher |

| Power Supply | AC100~240v, 50~60Hz, Single Phase |

| Accessories | Windshield, Signal Tower, USB, RS-232, Enthernet |