Check Weigher CWC M3-400/450

The Checkweigher CWC M3-400/450 is a specific model of checkweigher machine used in various industries for quality control and assurance in product packaging.

Suitable for various of medium and large size package.

Contact us for more

Our Experts are available to help

- Description

- BENEFITS OF USE

- SPECIFICATIONS

Description

Features

- Equipped with dynamic loadcell and high speed DSP

- Automatic product Guide, Zero Tracking and Trend Follow Up

- Barcode scanner and inkjet optional for automatic recipe shift and print

- Metric/Imperial and Normal/EU regulation shift

- 13 inches touch screen with Android system which support multiple languages

- Large system memory which supports ling term recording , fast seeking and recalling

- Supports graphic based production statistic and analysis

- Equipped with BLDC motor which is performing high speed and low dither

- Recording could be export to USB drive (CSV format)

- Data export by Ethernet port

- Various rejectors optional

- Tool-free conveyor

- Rejection feedback, air pressure monitor, fill up detection and locked bin optional

- SUS304 frame with height adjustable

The Checkweigher CWC M3-400/450 is another model of checkweigher machine used in various industries for quality control and assurance purposes. Here are some potential features and benefits associated with this model:

- High Accuracy Weighing: Like other checkweighers, the CWC M3-400/450 is likely designed to provide precise weight measurements, ensuring that products meet specified weight criteria.

- Versatility: It may be capable of handling a wide range of products and packaging types, accommodating different shapes, sizes, and materials commonly found in the industry.

- Efficiency: Automates the weighing process, helping to streamline production lines and increase throughput by quickly and accurately weighing items as they move along the conveyor belt.

- Reject Mechanism: Likely equipped with a reject mechanism to remove products that fall outside of the specified weight range, preventing non-compliant items from reaching consumers.

- Data Management: May feature data logging and reporting capabilities, allowing operators to track weight variations over time and make informed decisions to optimize production processes.

- Integration: Can potentially integrate with other production line equipment and software systems for seamless operation and enhanced data management.

- Compact Design: The “400/450” designation suggests a smaller footprint compared to larger models, making it suitable for installations where space is limited.

Overall, the Checkweigher CWC M3-400/450 offers similar benefits to other checkweigher models, including improved product quality, compliance with regulations, cost savings through reduced giveaway, and increased operational efficiency.

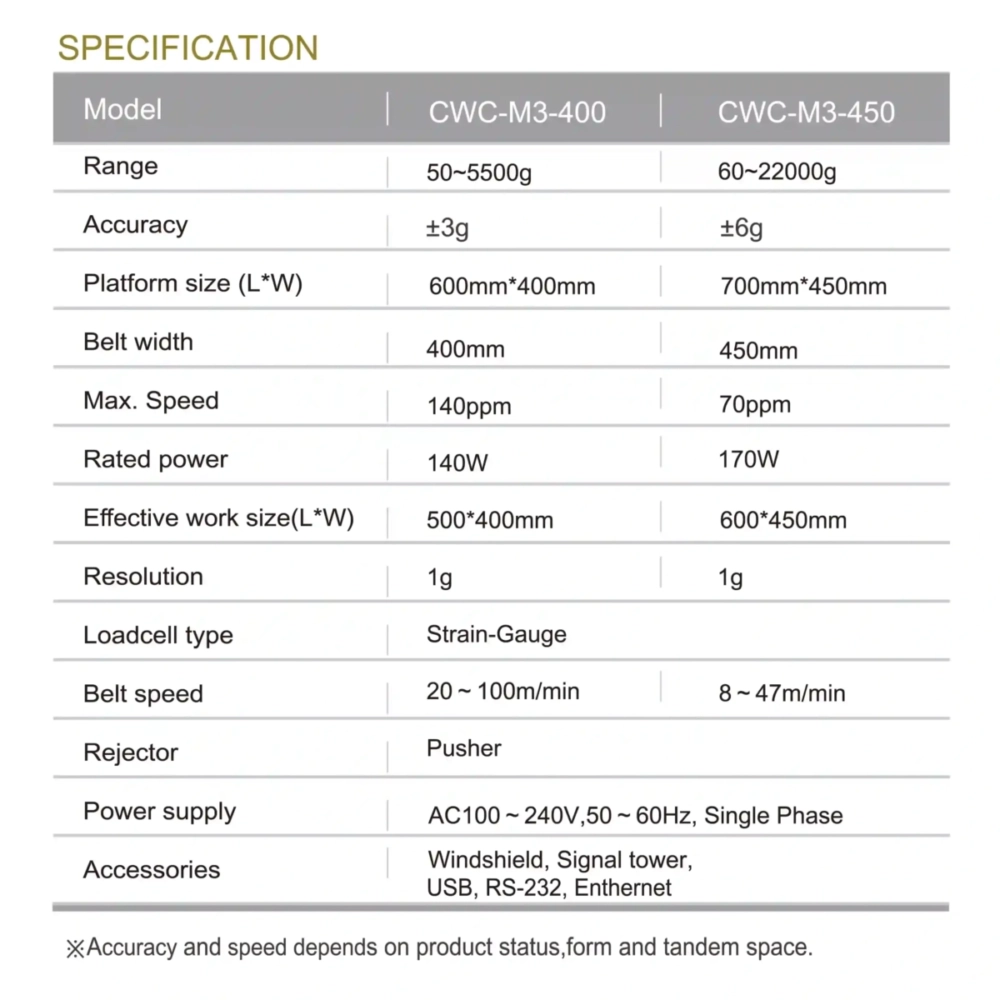

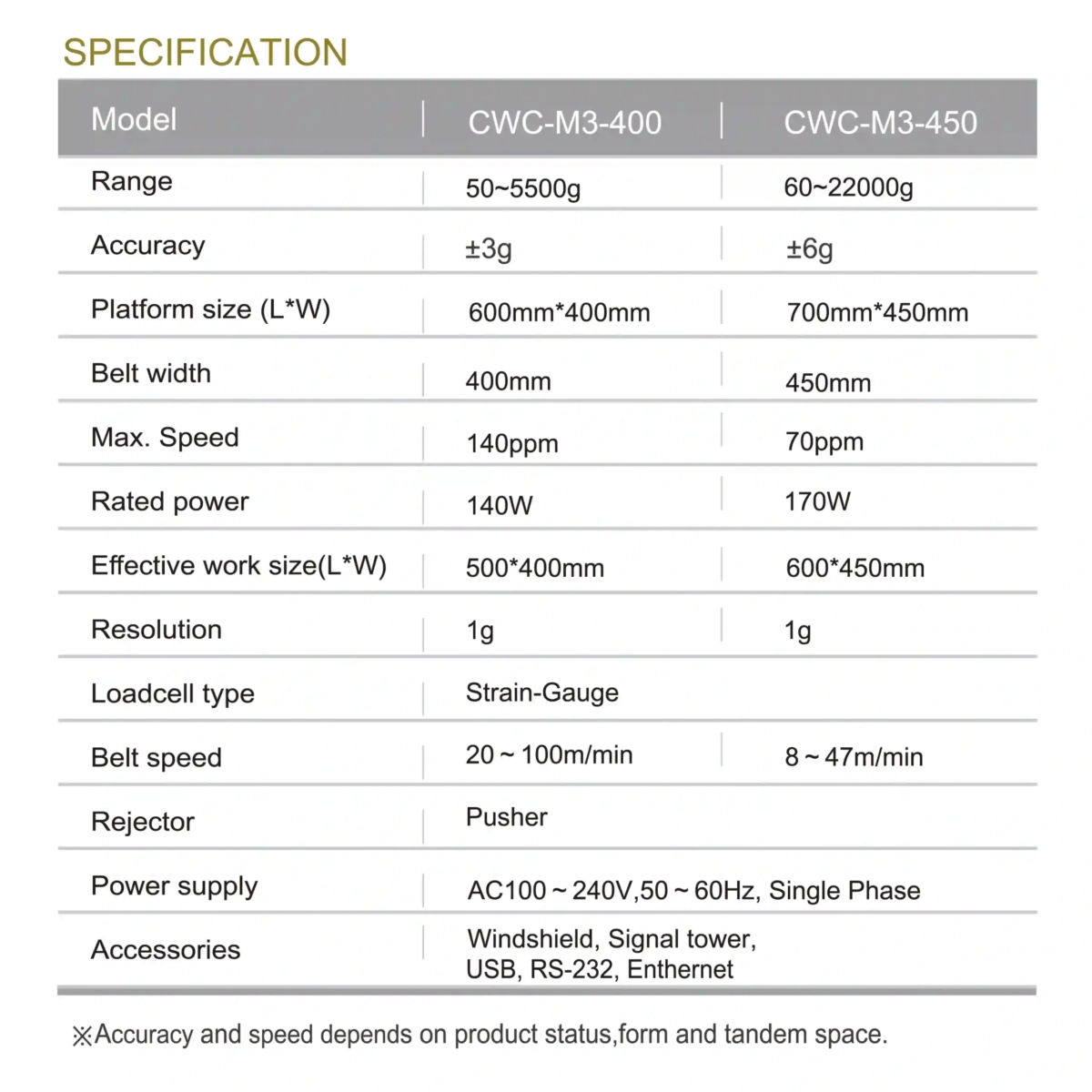

| Model | CWC-M3-400 |

| Range | 50~5500g |

| Accuracy | +/-3g |

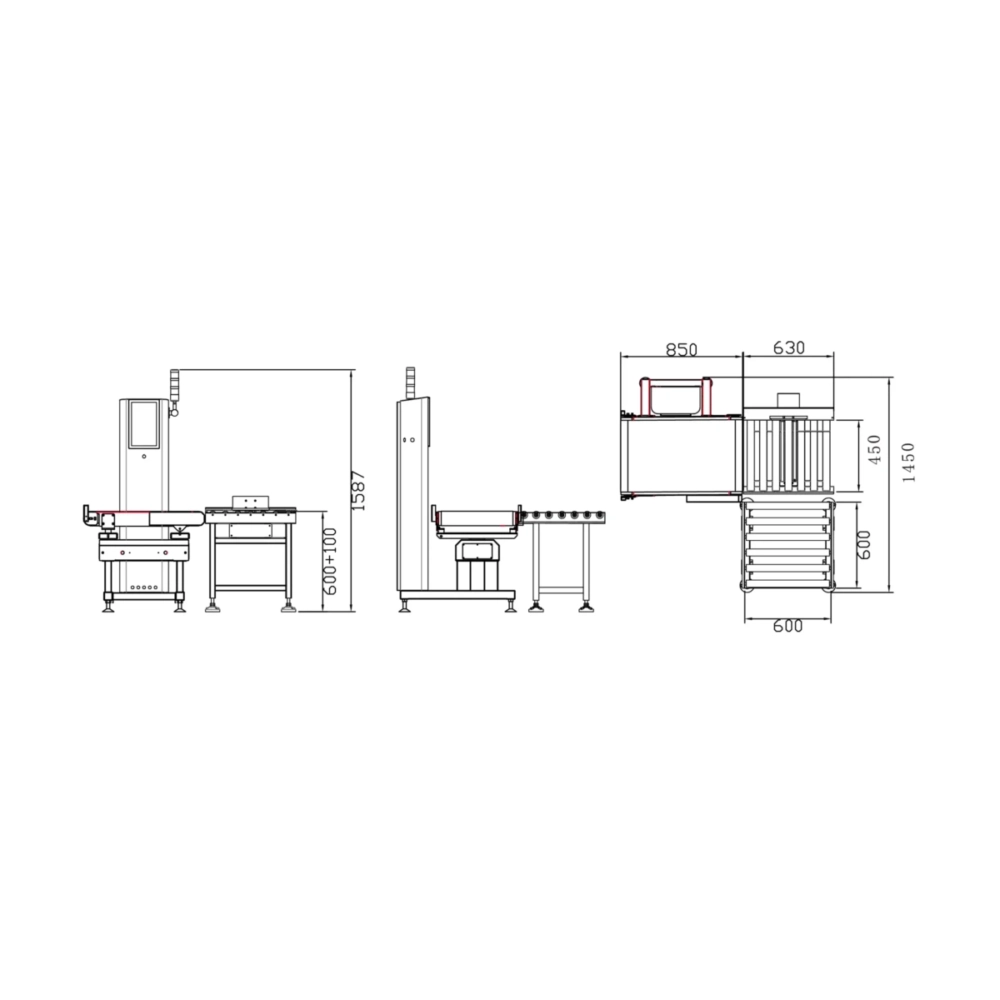

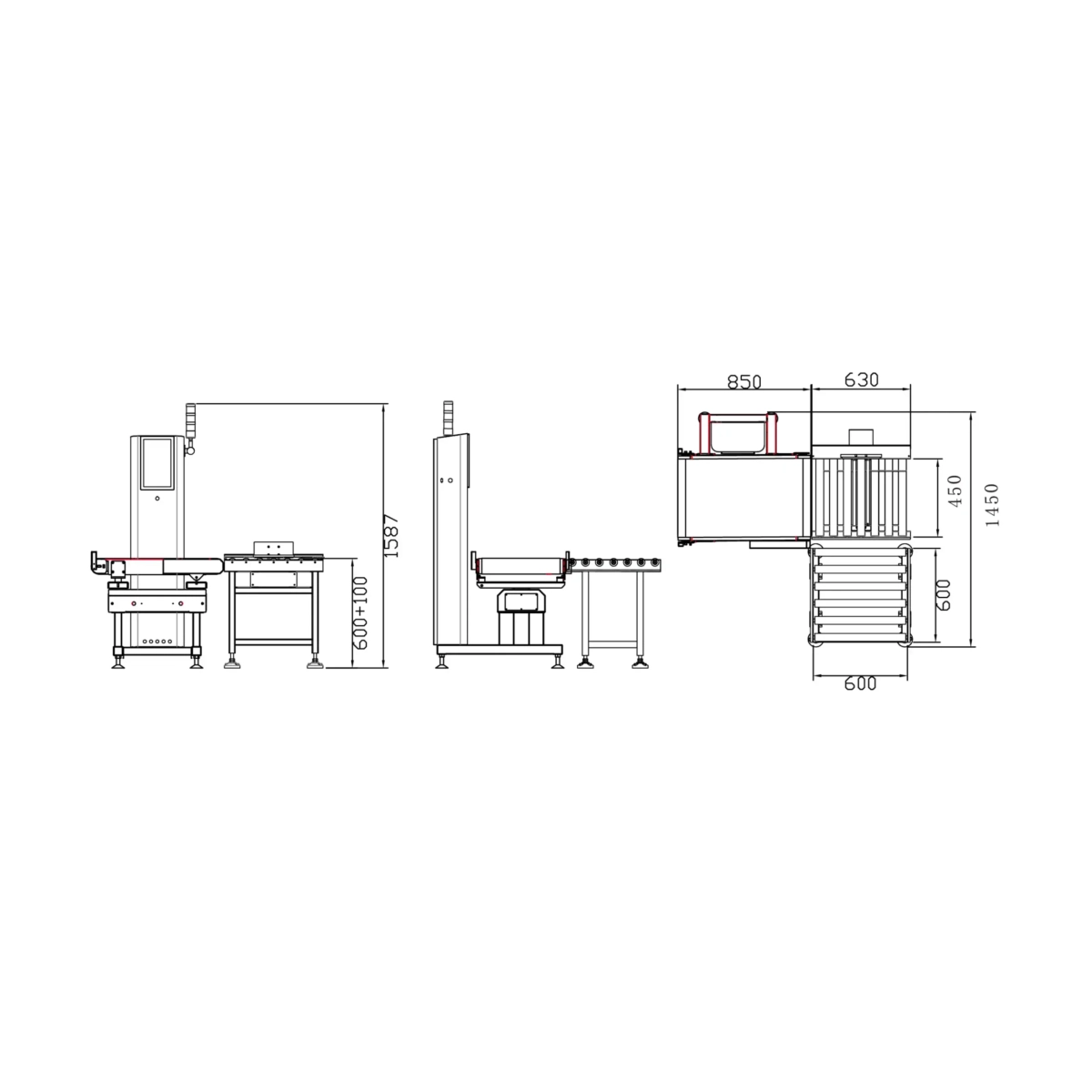

| Platform Size (L*W) | 600*400mm |

| Belt Width | 400mm |

| Max. Speed | 140ppm |

| Rated Power | 140W |

| Effective Work Size | 500*400mm |

| Resolution | 1g |

| Loadcell type | Strain-Gauge |

| Belt Speed | 20~100m/min |

| Optional Rejector | Pusher |

| Power Supply | AC100~240V,50~60Hz, Single Phase |

| Accessories | Windshield, Signal tower, USB, RS-232, Enthernet |

| Model | CWC-M3-450 |

| Range | 60~22000g |

| Accuracy | +/-6g |

| Platform Size (L*W) | 700*450mm |

| Belt Width | 450mm |

| Max. Speed | 70ppm |

| Rated Power | 170W |

| Effective Work Size | 600*450mm |

| Resolution | 1g |

| Loadcell type | Strain-Gauge |

| Belt Speed | 8~47m/min |

| Optional Rejector | Pusher |

| Power Supply | AC100~240V,50~60Hz, Single Phase |

| Accessories | Windshield, Signal tower, USB, RS-232, Enthernet |