Check Weigher CWC II 160/230/300

The Check Weigher CWC II 160/230/300 is an industrial machine used for accurately measuring the weight of products during production.

Suitable for most of package online weight sorting.

Contact us for more

Our Experts are available to help

- Description

- BENEFITS OF USE

- SPECIFICATIONS

Description

Features

- Equipped with dynamic loadcell and high speed DSP

- Automatic product guide and zero tracking

- Points configurable, real-time weight curve display

- 10 inches touch screen with Android system which support multiple languages

- Large system memory which supports long term recording, fast seeking and recalling

- Supports graphic-based production statistic and analysis

- Equipped with BLDC motor which is performing high speed and low dither

- Records could be exported to USB drive (CSV format)

- Various rejectors optional

- SUS304 frame with height adjustable

The Check Weigher CWC II 160/230/300 offers several benefits in industrial settings:

- Quality Control: Ensures that products meet specified weight requirements, maintaining consistency and quality throughout production batches. This is particularly crucial in industries where precise measurements are necessary for product integrity and compliance.

- Cost Reduction: Helps minimize product giveaway by identifying underweight or overweight items, thus reducing waste and optimizing product yield. This can lead to significant cost savings over time, improving overall profitability.

- Compliance Assurance: Assists in meeting regulatory standards and industry requirements for product weight accuracy. This ensures that products are compliant with legal regulations, quality standards, and labeling requirements.

- Increased Efficiency: Integrates seamlessly into production lines, enhancing workflow efficiency without causing disruptions. The CWC II 160/230/300 operates at a speed that matches the pace of the production line, minimizing bottlenecks and maximizing throughput.

- Versatility: Can handle a wide range of product sizes, shapes, and types, making it suitable for various industries such as food, pharmaceuticals, cosmetics, and more. This versatility allows for flexibility in production processes and accommodates diverse product lines.

- Integration Capabilities: Can be integrated with other production line equipment, such as conveyor systems and packaging machinery, facilitating automated processes and streamlining operations. Integration also enables real-time data sharing for better decision-making and process optimization.

- Data Management: Offers comprehensive data logging and reporting features, providing valuable insights into production performance, trends, and quality control metrics. This data can be used for analysis, troubleshooting, and continuous improvement initiatives.

- User-Friendly Operation: Designed with intuitive interfaces and user-friendly controls, making it easy to operate and maintain. This minimizes training time for operators and ensures smooth operation without extensive technical expertise.

In summary, the Check Weigher CWC II 160/230/300 offers benefits such as improved quality control, cost reduction, compliance assurance, increased efficiency, versatility, integration capabilities, data management, and user-friendly operation. These advantages make it an essential tool for enhancing productivity and ensuring product quality in industrial manufacturing environments.

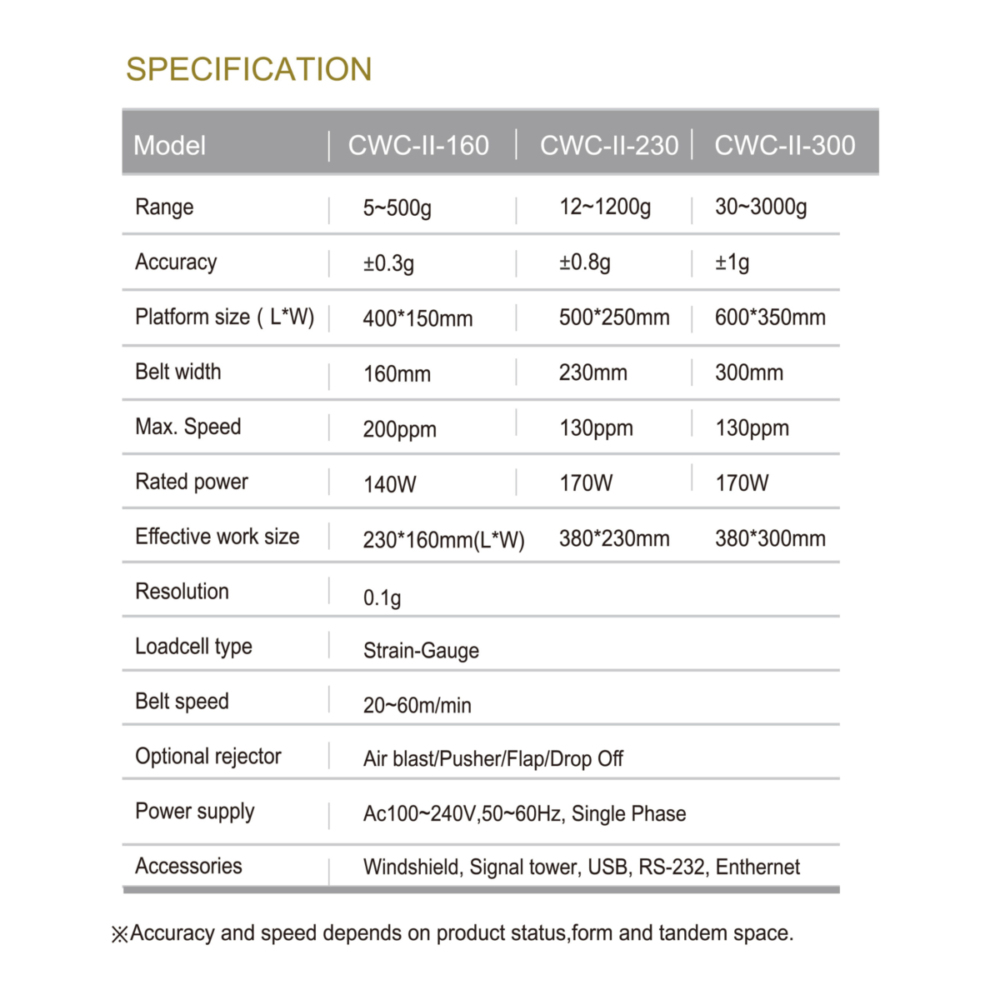

| Model | CWC-II-160 |

| Range | 5~500g |

| Accuracy | +/-0.3g |

| Platform Size (L*W) | 400*150mm |

| Belt Width | 160mm |

| Max Speed | 200ppm |

| Rated Power | 140w |

| Effective Work Size | 230*160mm (L*W) |

| Resolution | 0.1g |

| Loadcell Type | Strain Gauge |

| Belt Speed | 20~60m/min |

| Optional Rejector | Air blast/pusher/flap/Drop off |

| Power supply | AC 110~240V, 50~60Hz, Single phase |

| Accessories | Windshield, Signal Tower, USB, RS-232, Enthernet |

| Model | CWC-II-230 |

| Range | 12~1200g |

| Accuracy | +/-0.8g |

| Platform Size (L*W) | 500*250mm |

| Belt Width | 230mm |

| Max Speed | 130ppm |

| Rated Power | 170w |

| Effective Work Size | 380*230mm (L*W) |

| Resolution | 0.1g |

| Loadcell Type | Strain Gauge |

| Belt Speed | 20~60m/min |

| Optional Rejector | Air blast/pusher/flap/Drop off |

| Power supply | AC 110~240V, 50~60Hz, Single phase |

| Accessories | Windshield, Signal Tower, USB, RS-232, Enthernet |

| Model | CWC-II-300 |

| Range | 30~3000g |

| Accuracy | +/-1g |

| Platform Size (L*W) | 600*350mm |

| Belt Width | 300mm |

| Max Speed | 130ppm |

| Rated Power | 170w |

| Effective Work Size | 380*230mm (L*W) |

| Resolution | 0.1g |

| Loadcell Type | Strain Gauge |

| Belt Speed | 20~60m/min |

| Optional Rejector | Air blast/pusher/flap/Drop off |

| Power supply | AC 110~240V, 50~60Hz, Single phase |

| Accessories | Windshield, Signal Tower, USB, RS-232, Enthernet |