Check Weigher CWC M3-600

The CWC M3-600 is a type of checkweigher, a machine commonly used in manufacturing and packaging industries to ensure that products are within specified weight limits.

Suitable for various of large size package. Especially for cartoon box.

Contact us for more

Our Experts are available to help

- Description

- BENEFITS OF USE

- SPECIFICATIONS

Description

Checkweighers like the CWC M3-600 are essential for ensuring product quality control by verifying that items are within specified weight limits. This particular model likely has features such as high accuracy weighing, a conveyor system for product movement, reject mechanisms for out-of-spec items, and possibly integration with other production line equipment or software systems for data logging and analysis.

Features

- Dual Loadcell with high speed DSP

- Automatic product Guide, Zero Tracking and Trend Follow Up

- Barcode scanner and inkjet optional for automatic recipe shit and print

- Metric/Imperial and Normal/EU regulation shift

- 13 inches touch screen with Android system which support multiple languages

- Large system memory which supports long term recording, fast seeking and recalling

- Supports graphic based production statistic and analysis

- Records could be export to USB drive (CSV format)

- Data export by Ethernet port

- Platform size expandable and weighing rand extendable

- SUS304 frame

The Checkweigher CWC M3-600 offers several benefits to industries where precise weight control is essential:

- Quality Assurance: Ensures that products meet weight specifications, maintaining consistency and quality standards. This reduces the risk of underweight or overweight products reaching consumers, which could lead to dissatisfaction or non-compliance with regulations.

- Cost Savings: Helps minimize product giveaway by accurately weighing items, reducing waste and maximizing yield. Additionally, it can prevent costly fines or penalties associated with selling products that don’t meet weight regulations.

- Efficiency: Automates the weighing process, increasing production efficiency by quickly and accurately checking the weight of items as they move along the production line. This reduces the need for manual labor and speeds up throughput.

- Real-Time Monitoring: Provides real-time data on weight variations, allowing operators to identify and address issues promptly. This enables proactive maintenance and adjustments to optimize production processes.

- Traceability and Compliance: Facilitates traceability by recording weight data for each product, which is crucial for compliance with industry regulations and quality standards. This data can be stored for auditing purposes or used for process improvement initiatives.

- Versatility: The CWC M3-600 may offer flexibility in handling a variety of products and packaging types, adapting to different shapes, sizes, and materials commonly used in the industry.

- Integration: Can integrate with other production line equipment and software systems, such as labeling machines or ERP systems, streamlining operations and enhancing overall automation and data management capabilities.

Overall, the Checkweigher CWC M3-600 enhances product quality, operational efficiency, and compliance in manufacturing and packaging processes, ultimately leading to improved customer satisfaction and profitability.

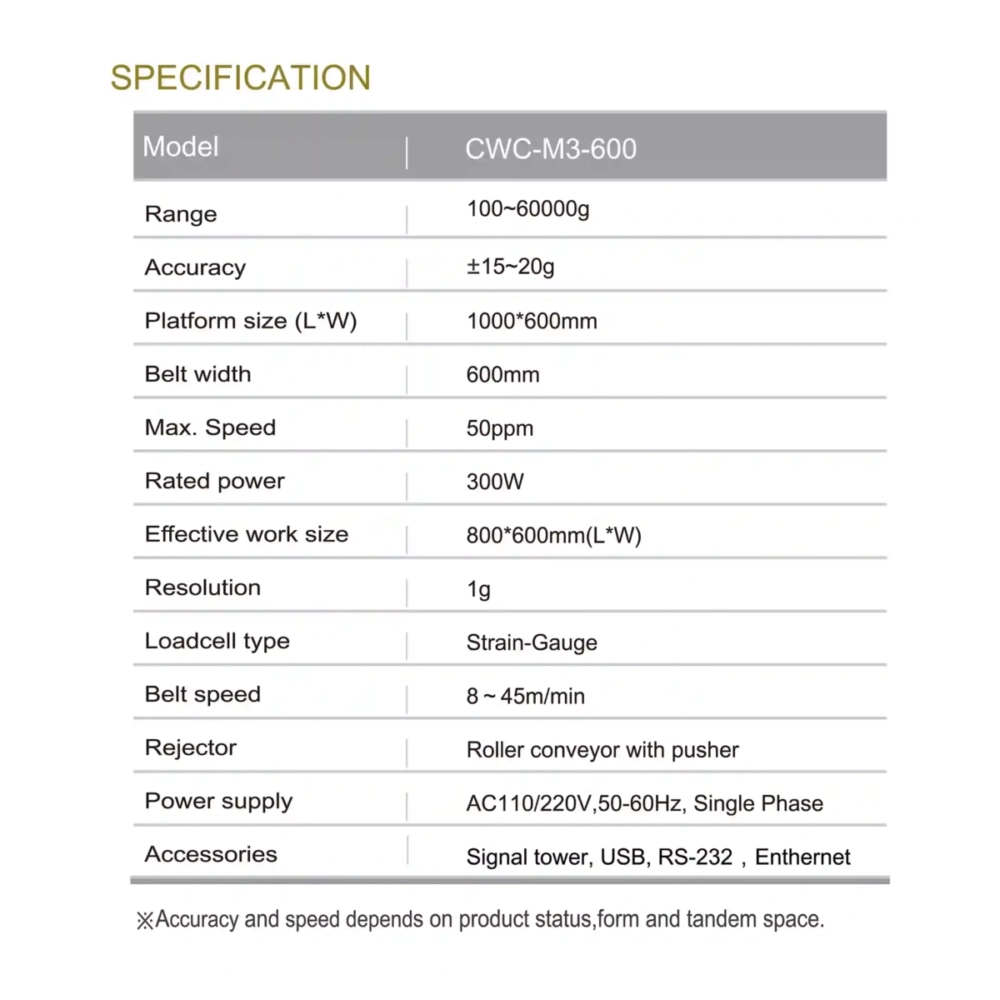

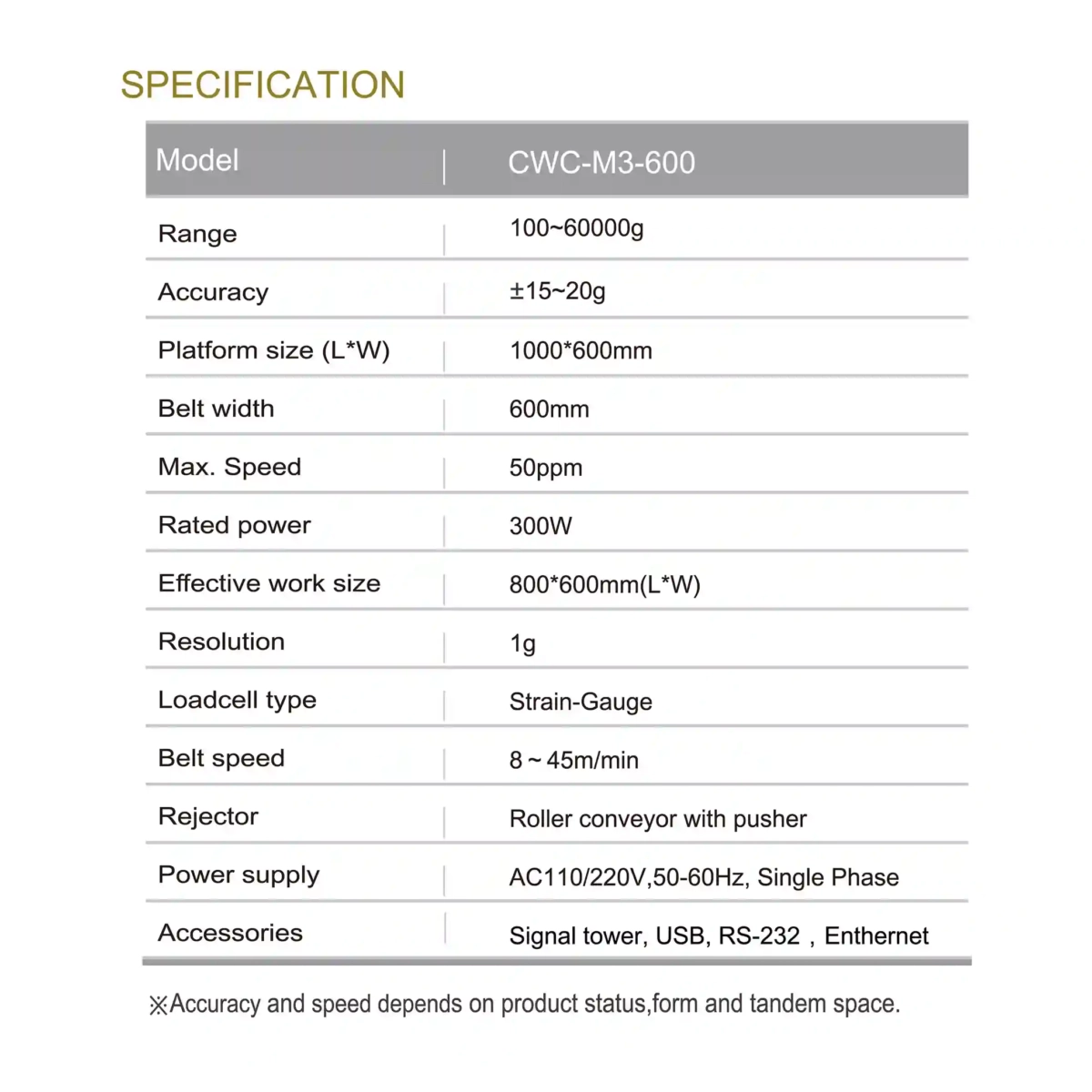

| Model | CWC-M3-600 |

| Range | 100~60000g |

| Accuracy | +/15g~20g |

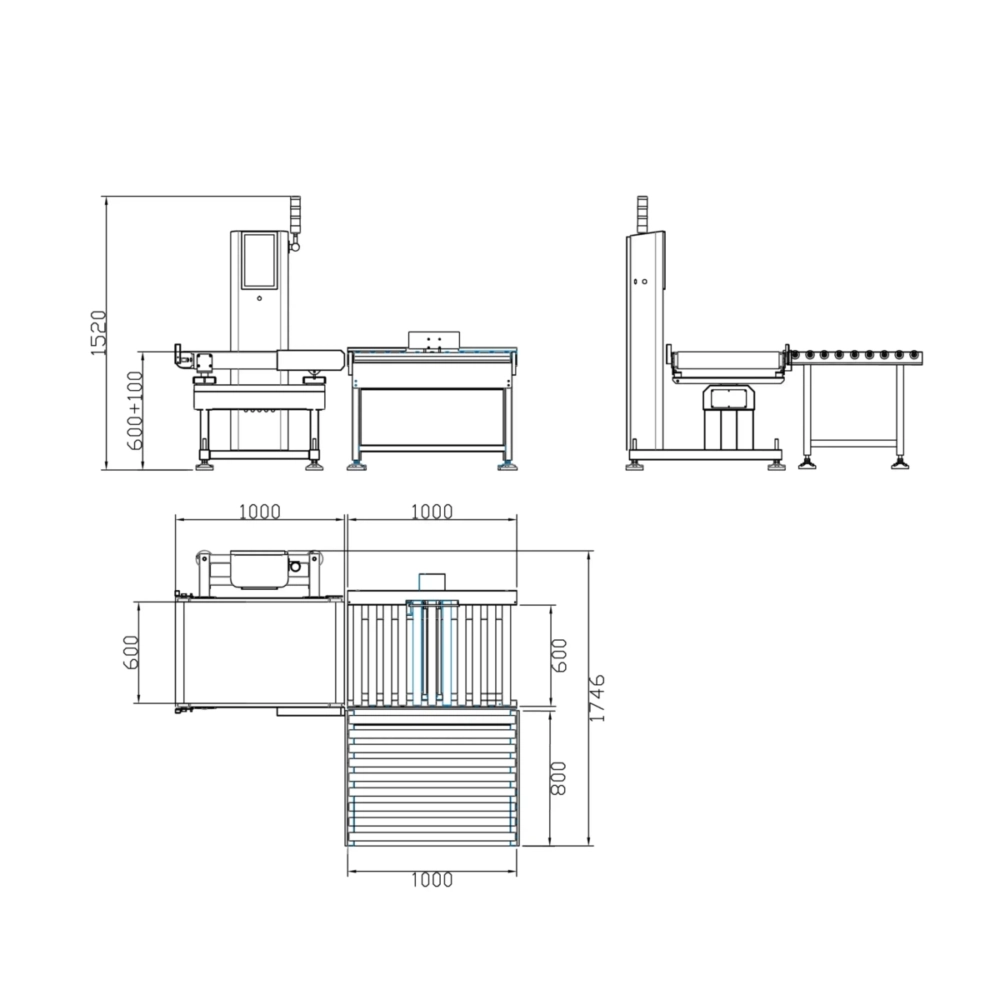

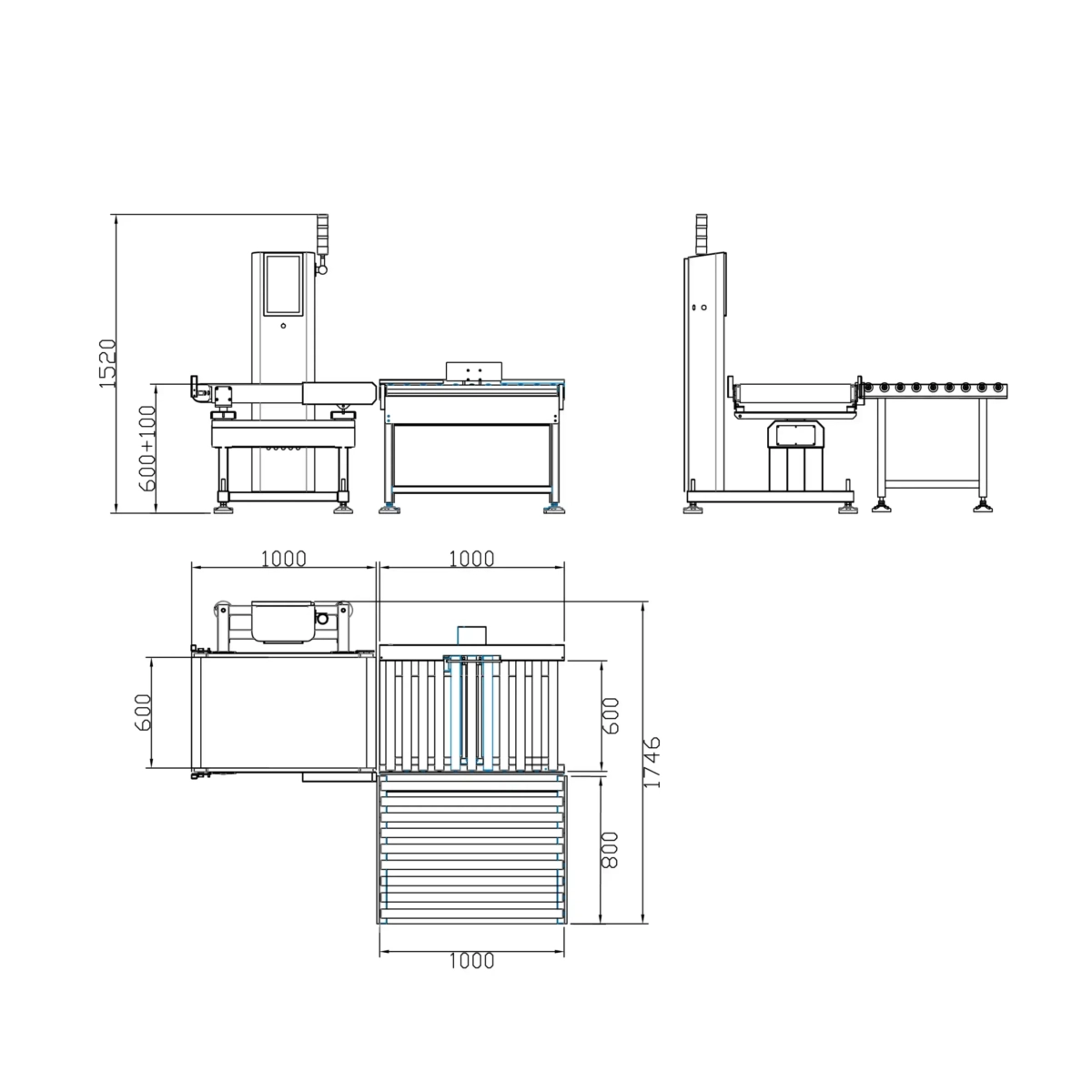

| Platform Size (L*W) | 1000*600mm |

| Belt Width | 600mm |

| Max. Speed | 50ppm |

| Rated Power | 300W |

| Effective Work Size | 800*600mm (L*W) |

| Resolution | 1g |

| Loadcell type | Strain-Gauge |

| Belt Speed | 8~45m/min |

| Optional Rejector | Roller conveyor with pusher |

| Power Supply | AC100~220V,50~60Hz, Single Phase |

| Accessories | Signal tower, USB, RS-232, Enthernet |